华卓塑料焊接专家

热板焊接

热板焊接是将两块塑料加热并压合在一起直至熔合的过程。热板焊接有几种不同的类型。每种技术对部件施加热量和压力的方式各不相同,但基本步骤相同——加热、施加压力和冷却。塑料焊缝是由牢固的分子键形成的。根据所使用的焊接技术,焊缝会被密封。

高效率和低成本:有不可或缺的作用

热板焊接设备在汽车中央控制台的运用

华卓热板焊接设备系列包含各种尺寸的机型,适用于焊接不同尺寸的部件。在汽车行业中,常见应用包括手套箱、中控台和地图盒内衬。在热板焊接过程中,塑料部件通过辐射热与电热板接触进行焊接。尽管涉及接触,但该工艺无颗粒,能够为多种塑料形成非常牢固且完全密封的焊缝。

即使是具有复杂3D轮廓的薄壁零件,也能通过这一成熟可靠的工艺进行可靠加工。现代化的换刀系统、先进的驱动技术以及适度的自动化程度,不仅提升了生产效率,也使这一成熟的工艺在众多行业和应用领域中极具吸引力。

现代接触焊接

热板焊接工艺

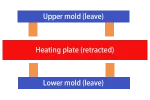

热板焊接是一个多步骤的工艺,因为零件的加热和连接是分开进行的。将零件插入夹具后,将其放置在电加热板上。零件与热板接触后,焊接过程开始,焊接过程分为三个阶段:

熔化、打开、密封

大尺寸和复杂几何形状

热板焊接的应用

- 汽车行业的大型部件,包括仪表板、门板、中央控制台

- 空气或其他过滤器外壳

- 水箱系统/水箱过滤器

- 具有复杂 3D 焊缝轮廓的零件

- 空气管道

热板焊接冷却壶

热板焊接汽车车灯

热板焊接汽车车灯

华卓热板焊接设备的优势

可焊接具有复杂 3D 焊缝轮廓的零件

牢固、完全紧密的焊缝

适用于多种塑料

大面积焊接

大批量生产周期短

热板焊接设备参数

- 输送电机:伺服电机

- 动力源:电力+气压

- 气缸:亚德客

- 液压站:/

- 限位器控制:气缸

- 节流阀调整:调压阀/比例阀

- 机器外形尺寸:2700*1900*1990

- 设备重量/模具重量:4T/1.5T

- 上下模尺寸:855*500*450(定制)

- 热模尺寸:定制

- 设备换模位置:前端换模

- 模具尺寸:1100*800*450

- PLC控制器:Siemens

- 温控点数:8

- 上下模速度:定制

- 热模速度:定制

- 合膜压力:根据产品大小

- 上/下模具重量:根据产品大小

- 热模模具重量:根据产品大小

- Hot mold mold weight: according to product size

- 设备开模尺寸:1400mm

- 上模行程:300mm

- 位置精度:0.05mm

- 模具位置精度:0.1mm