Huazhuo Plastic Welding Expert

Ultrasonic welding plastic

We specialize in manufacturing ultrasonic welding for plastic welding machines. Our ultrasonic plastic welding is designed to meet the high demands of the automotive industry, providing reliable and efficient performance for all your Automobile production needs.

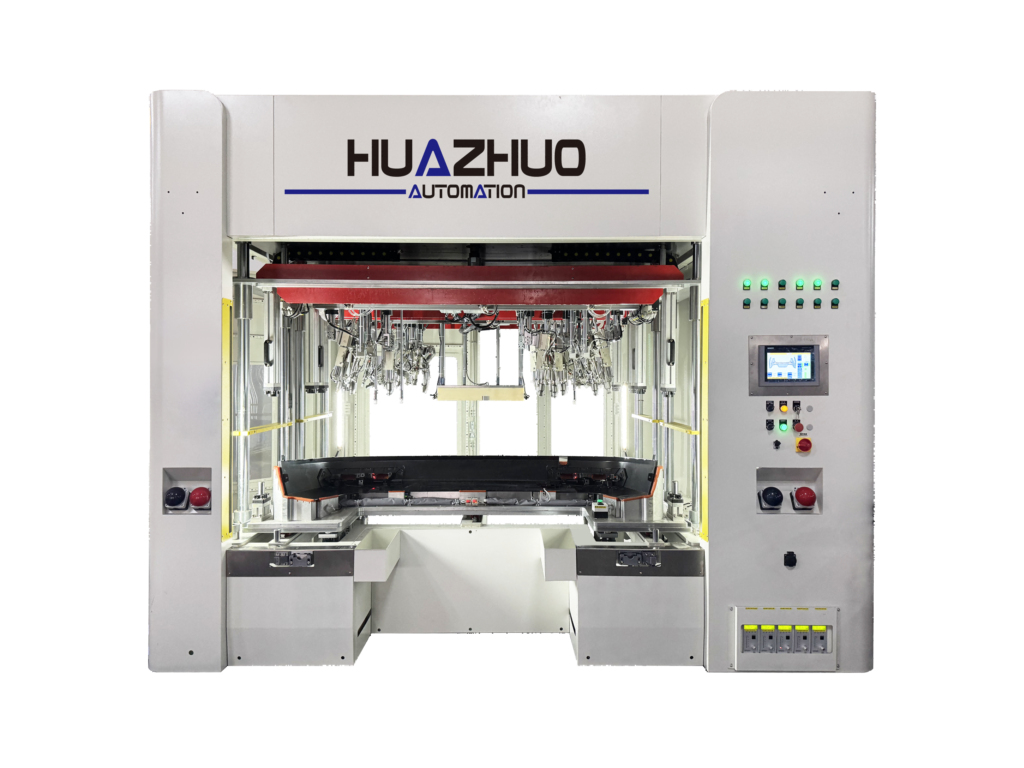

Ultrasonic Welding machine: Complete Car Assembly in only 1 Minute

Maximize your production efficiency with our ultrasonic plastic welding machines

Our ultrasonic plastic welding equipment represents high efficiency and precision. Each welding point only takes 5-8 seconds, and you will get a perfect car component in no more than 1 minute. Each welding unit has a displacement sensor, which can independently control the welding position depth and multi-angle adjustment. This makes our ultrasonic welding machines a cost-effective solution that significantly increases operational efficiency.

Quick mold change

Optional tool library

customization

Classification of ultrasonic plastic welding:

"

Since 2012, our expertise in producing plastic ultrasonic welding equipment has reached a high level. However, our exceptional proficiency truly shines in the automated welding of automotive accessories such as door panels and bumpers, where our refined processes yield outstanding products for our clients.

"

Ultrasonic plastic welding machine maximizes the efficiency of plastic welding production in automobiles and other fields

Ultrasonic plastic welding is a highly effective technique for creating strong connections between two or more materials of the same type and those of different types. It is particularly suited for welding thermoplastics.

The process uses ultrasonic waves at 20 to 70 kHz with amplitudes of 5 to 50 μm, delivered through a sonotrode. These waves generate frictional heat at the material interface, melting the plastics. The melted materials are then pressed together to form a strong bond.

The plastics are then joined under additional pressure. The energy from the sound waves must be focused on welding precisely with ultrasonics.

Maximizing Automotive Accessories Production Efficiency:The Perks of Premium Ultrasonic plastic Welding

- The ultrasonic system with energy control has a powerful self-protection system.

- Each welding unit has a displacement sensor, and can independently control the depth of the welding position.

- The ultrasonic welding unit allows for multiple angle adjustments, suitable for various automobile doors.

- The servo motor has fast control speed, high precision, and high efficiency

Equipment parameters Of ultrasonic welding plastic

- Product application: flat surface, puncture, interior and exterior riveting

- Ultrasonic frequency: 35KHZ

- Output power: 10Kw

- Welding mode: ultrasonic welding

- Fetal membrane material: aluminum + ABS

- Input power: 380v

- Input air pressure: >=6par

- Production method: 24-hour continuous production

- Robot brand: ABB, FANUC, customized

- Robot arm brand: customized

- Number of machine stations: 2

- Pneumatic configuration: SMC

- Grating: SICK

- PLC controller: Sienmens

- Generator power: 35KHZ

Auto Pillar Ultrasonic Welding

Auto Bumper Ultrasonic Welding