Huazhuo Plastic Welding Expert

Ultrasonic punching and welding machine

Gentle punching by means of ultrasound into painted bumpers without marks. The paint is drawn in and the defined radius is cleanly embossed into the paint layer. In the next step, brackets, clips or frames are welded on using ultrasound.

Precision. Efficiency. Integration.

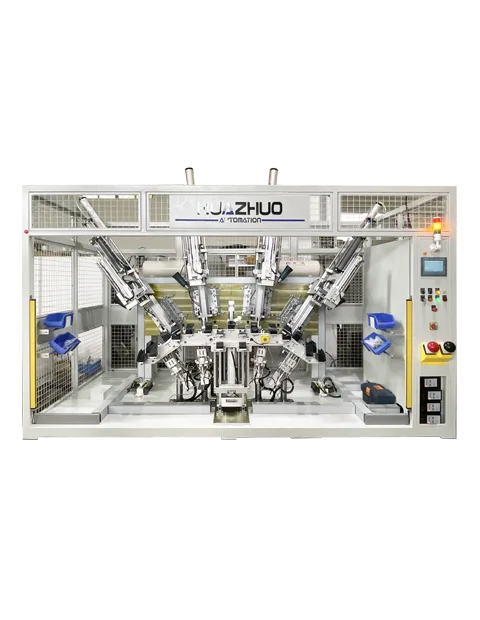

Ultrasonic punching and welding machine

The Huazhuo Punching and Welding Machine is a high-performance, integrated solution that combines precision punching and advanced plastic welding into a single automated process. Designed to meet the rigorous demands of automotive interior, appliance, and plastic component production, this equipment streamlines your workflow, reduces labor, and ensures consistent product quality.

Integrated equipment helps the development of automotive interior and exterior decoration

Automobile bumper ultrasonic punching and welding machine

- Bumper with hybrid module

- Inserting the hybrid module and the bumper

- Sliding table moves the bumper to the punching unit

- Punching and radius stamping is done with one punching tool

- Hole with radius stamping in the bumper after punching

- Sliding table moves the bumper back to the starting position

- Counterbolder moves into position before the welding process starts

- Ultrasonic welding joints the parts together

- Ultrasonic punching and welding in one process

Ultrasonic punching and welding machine Processes

A punching and welding machine is a multi-functional industrial system that integrates material punching with welding into a single automated process. It’s designed for high-efficiency production of plastic components that require precise shaping and reliable assembly.

This type of machine is widely used in automotive interior manufacturing, electrical enclosures, and plastic product assembly.

Place the bumper bracket on the fixture, punch holes according to the designed hole positions and diameters, then move into the welding area where the welding device will weld the bracket following the predetermined welding path and parameters.

key FEATURES of Ultrasonic punching and welding machine

Combines punching and welding operations in one unit — eliminating the need for separate machines and manual handling.

Supports a variety of punch and die shapes as well as welding methods (ultrasonic, hot plate, or riveting) for different material types and product designs.

Equipped with a PLC + HMI interface for easy operation, precise parameter setting, and real-time monitoring.

Reduces cycle time through automated transitions between punching and welding, boosting output efficiency.

All-in-one structure minimizes equipment footprint in your production area.

China plastic welding expert

WHY CHOOSE HUAZHUO punch welding machine?

With over 12 years of experience in plastic welding automation, Huazhuo Automation delivers durable, precise, and customizable solutions trusted by leading manufacturers such as BYD, Great Wall Motors, and more. Our team provides full support from design to after-sales service.

Integrated Operation

Faster cycle time, fewer handling steps

High Repeatability

Consistent quality on every part

Reduced Labor & Downtime

Less manual intervention needed

Factory Smart Integration

Ready for automation and data capture