Huazhuo Plastic Welding Expert

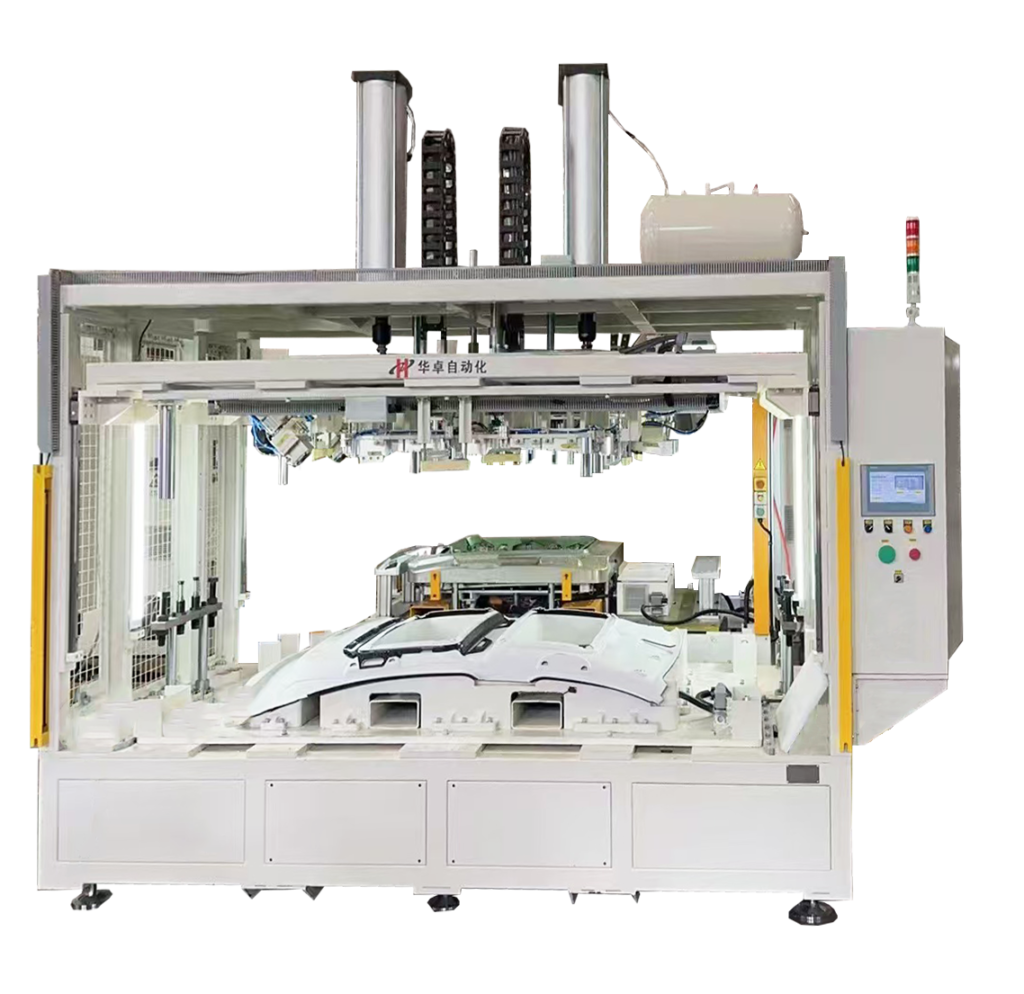

covering and laminating machine

Covering and Laminating machine is used specifically for the manufacturing and laminnating of interior and exterior automotive components.

Model: HZ-BF-2680

- Working stroke: 75MM-125MM

- Welding time: 0.01-9.99SEC

- Dimensions: L3400MM×W1885MM×H3600MM

- Weight: 5T

- Working cycle: 75-90 seconds/piece

- Application : Car door armrests, front and rear passenger side trims, upper decorative panels, Dashboard、Console、Car door panel…

Equipment advantages

1.The equipment is equipped with a high-precision sensing system that allows for accurate positioning according to design specifications.

2.It features a customized clamping system that can accommodate the wrapping needs of various types and sizes of interior and exterior trim components.

3.The equipment automatically completes the wrapping process,reducing labor costs and production time.

4.It is suitable for automotive interior and exterior trim components such as armrests,door panel trims,dashboards,and center consoles.

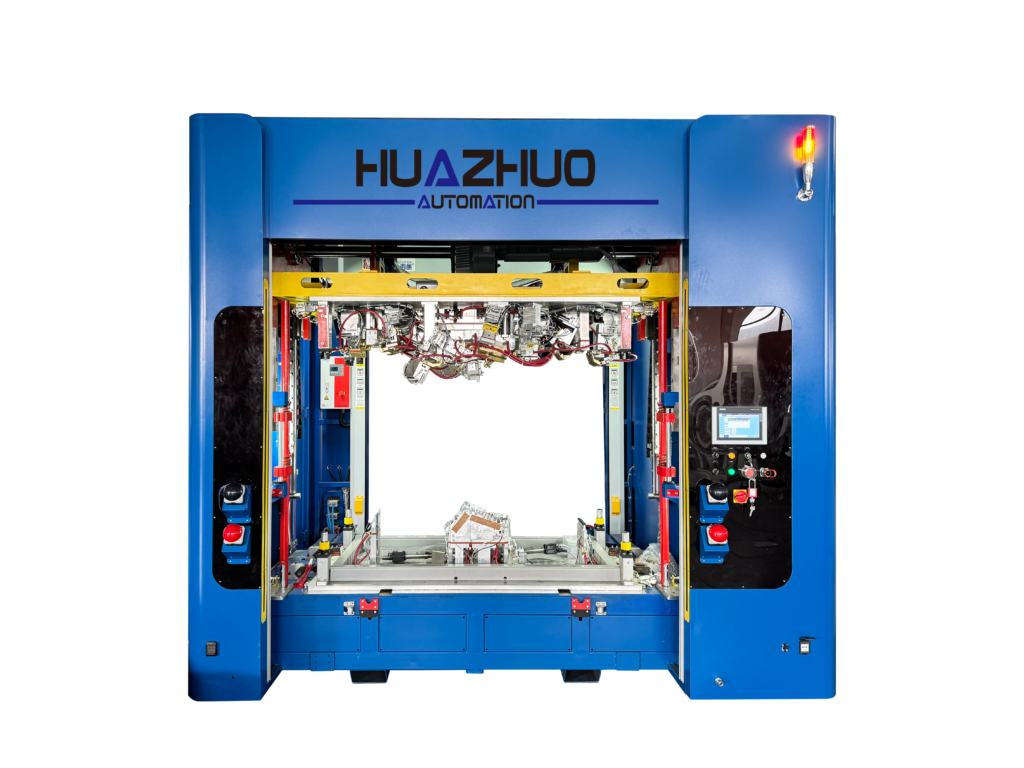

Car roof covering

Functional features:

1. This equipment is suitable for leather wrapping and edging of automotive interior parts, alignment positioning, vacuum activation, and male mold forming.

2. The equipment has an independent temperature control system and cooling system, which can continuously provide a constant temperature for glue activation; the lower clamping device uses a servo motor to drive precise positioning; the mold can be quickly replaced.

3. The equipment frame consists of two parts. The lower frame is welded with high-quality A3 square tubes, and the upper frame is welded with A3 square tubes or overlapped with European standard aluminum profiles, with exquisite appearance.

Pillar guard plate edge welding equipment

Equipment parameters Of covering and laminating Machine

- PLC Controller:Siemens

- Power source:Electricity+Air

- Vacuum Pressure Value:0-0.075MPa

- Machine Dimensions:3600*2700*2600

- Mold Dimensions(mm):2670*110*100

- pneumatic components:Airtac/SMC

- pneumatic components:Airtac/SMC

- Die Change Location:Front Loading

- Equipment Weight:7000kgs