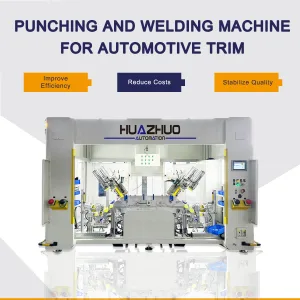

Huazhuo Plastic Welding Expert

Boosting Bumper Production Efficiency: Ultrasonic Punching & Welding in One Integrated Process

How Ultrasonic Punching and Welding Technology Transforms Bumper Hybrid Module Production

With the fast-growing demand for lightweight, precision-engineered automotive components, manufacturers are seeking equipment that can reduce cycle time, maintain tight tolerances, and ensure repeatable product quality. One of the most effective solutions is the ultrasonic punching and welding integrated machine, which combines multiple processes into a single automated workflow. This technology is especially valuable in the production of automotive bumpers, hybrid module assemblies, and plastic exterior parts.

In this article, we take an in-depth look at how the integrated process works—and why more automotive suppliers are adopting this innovative system to stay competitive.

Step-by-Step Overview of the Ultrasonic Punching & Welding Process

1.Hybrid Module and Bumper Insertion

The process starts with the operator placing both the hybrid module and the plastic bumper into a precision-engineered fixture.

The fixture is designed with:

- Positioning pins

- Contoured surfaces

- Mechanical clamps

to ensure stable, accurate placement. This step is crucial because even a small misalignment can affect downstream punching accuracy and welding strength.

2. Automated Transfer to the Punching Station

A servo-driven sliding table then moves the bumper assembly into the punching unit.

Servo motion ensures:

- Smooth transfer

- High positioning accuracy

- Repeatable movement

This automation minimizes manual intervention and reduces the risks of dimensional errors.

3. Punching and Radius Stamping — Performed with One Tool

At the punching station, a multifunction punching tool performs two operations simultaneously:

- Hole punching

- Radius stamping

This unified tool design enhances precision by keeping the part fixed in a single clamping state.

Technical benefits include:

- Reduced cycle time

- Lower tooling costs

- Consistent radius geometry

- Clean, burr-free punching edges

- Improved downstream fitment accuracy for the hybrid module

The result is a perfectly stamped hole with the required radius, essential for high-quality bumper assembly.

4. Inspecting the Post-Punching Result

After punching is completed, the machine provides a clear, uniform hole with integrated radius stamping.

Depending on configuration, a vision inspection or sensor verification system can be added to:

- Confirm hole dimensions

- Verify part presence

- Detect punching faults

This ensures that only compliant parts enter the welding phase.

5. Return to Starting Position for Welding

The servo sliding table retracts, bringing the bumper back to the original welding position. This synchronized motion eliminates unnecessary handling and keeps the production cycle continuous and efficient.

6. Counterholder Positioning for Structural Support

Before ultrasonic welding begins, the counterholder moves precisely into place.

The counterholder:

- Supports the backside of the bumper

- Maintains flatness

- Prevents deformation under ultrasonic pressure

- Ensures optimal energy transfer during welding

This step is especially critical for large, flexible plastic exterior components like bumpers.

7. Ultrasonic Welding — High Strength, Clean, and Repeatable

With the counterholder in position, the ultrasonic welding system activates.

During welding:

- The ultrasonic horn vibrates at high frequency

- Mechanical vibrations create heat at the weld interface

- Plastic material melts and bonds the hybrid module firmly to the bumper

Advantages of ultrasonic welding for bumpers include:

- Short weld cycles

- Clean and flash-free surfaces

- No need for adhesives or solvents

- Excellent mechanical strength

- Precise control of welding parameters (amplitude, pressure, time)

This makes it ideal for manufacturing automotive exterior components, structural bumper parts, and plastic hybrid assemblies.

Why the Integrated Process Matters for Automotive Manufacturers

By combining ultrasonic punching and welding into one automated workflow, this system offers major competitive advantages:

✔ Higher Production Efficiency

Two processes—punching and welding—are completed in one machine.

This reduces equipment quantity, floor space, and operator workload.

✔ Improved Accuracy and Repeatability

The part stays in the same fixture throughout the process, ensuring:

No secondary positioning errors

Higher dimensional accuracy

Stable weld strength

✔ Lower Cost of Ownership

Manufacturers benefit from:

Reduced tooling changes

Lower maintenance costs

Shorter cycle times

Fewer quality rejects

✔ Ideal for Automotive Bumper and Plastic Component Production

The system is widely used for:

Bumper hybrid module installation

Exterior trim welding

Large automotive plastic parts

Structural reinforcement modules

Decorative plastic covers