Huazhuo Plastic Welding Expert

Robot inserts clips

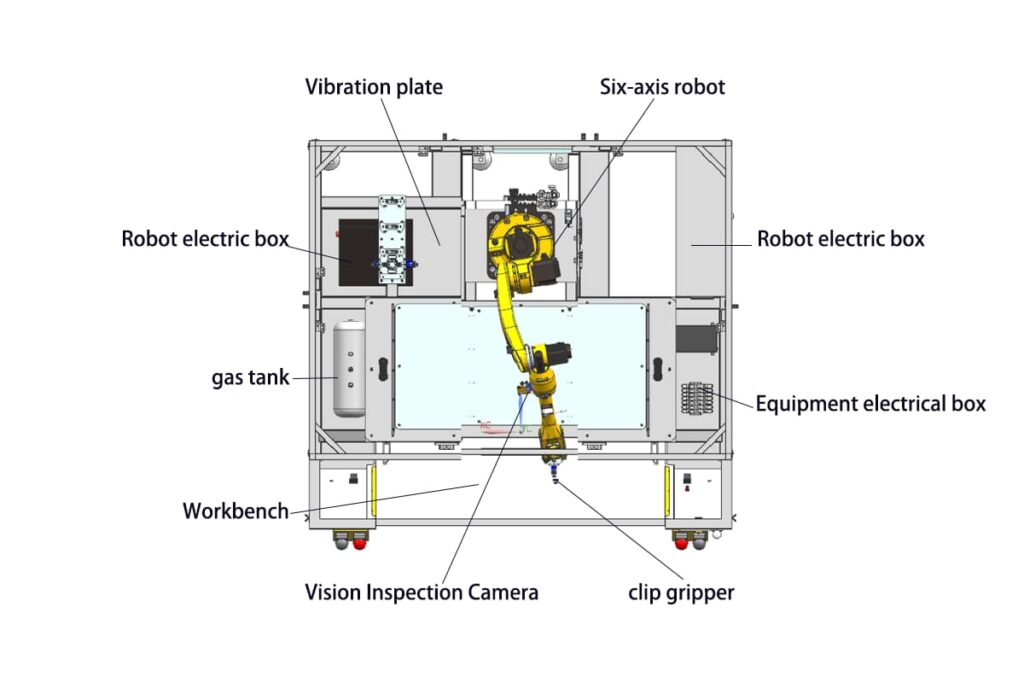

The Robotic Clip Insertion System, with a 6-axis industrial robot, vision system, and vibration feeder, enables efficient, precise, and intelligent clip mounting, significantly improving production efficiency and consistency.

Automated inserts clips machine reduces production costs

Robotic inserts clips Solution

Huzhou Huazhuo Automation Equipment Co., Ltd. has developed a proprietary robotic clip insertion solution for automotive interior and exterior components such as tailgate trims and front cowl covers. Backed by over a decade of expertise in plastic welding and assembly, this system offers flexible design, fast mold change, precision positioning, and smart visual inspection, making it ideal for OEMs and Tier-1 suppliers.

Maximize work efficiency and qualification rate

Key Advantages of Robot inserts clips

Flexible

Supports fast mold change within 10 minutes for multiple model variants

Precise

±0.1mm fixture positioning accuracy ensures consistent clip alignment

Efficient

≤50s cycle time fits high-speed production lines

Reliable

MTBF ≥ 1200 hours, jamming rate < 1%

Smart

CCD vision inspection for real-time error-proofing

Safe

Integrated emergency stop and light curtain protection

Structural Overview & Functional Breakdown of robot inserts clips

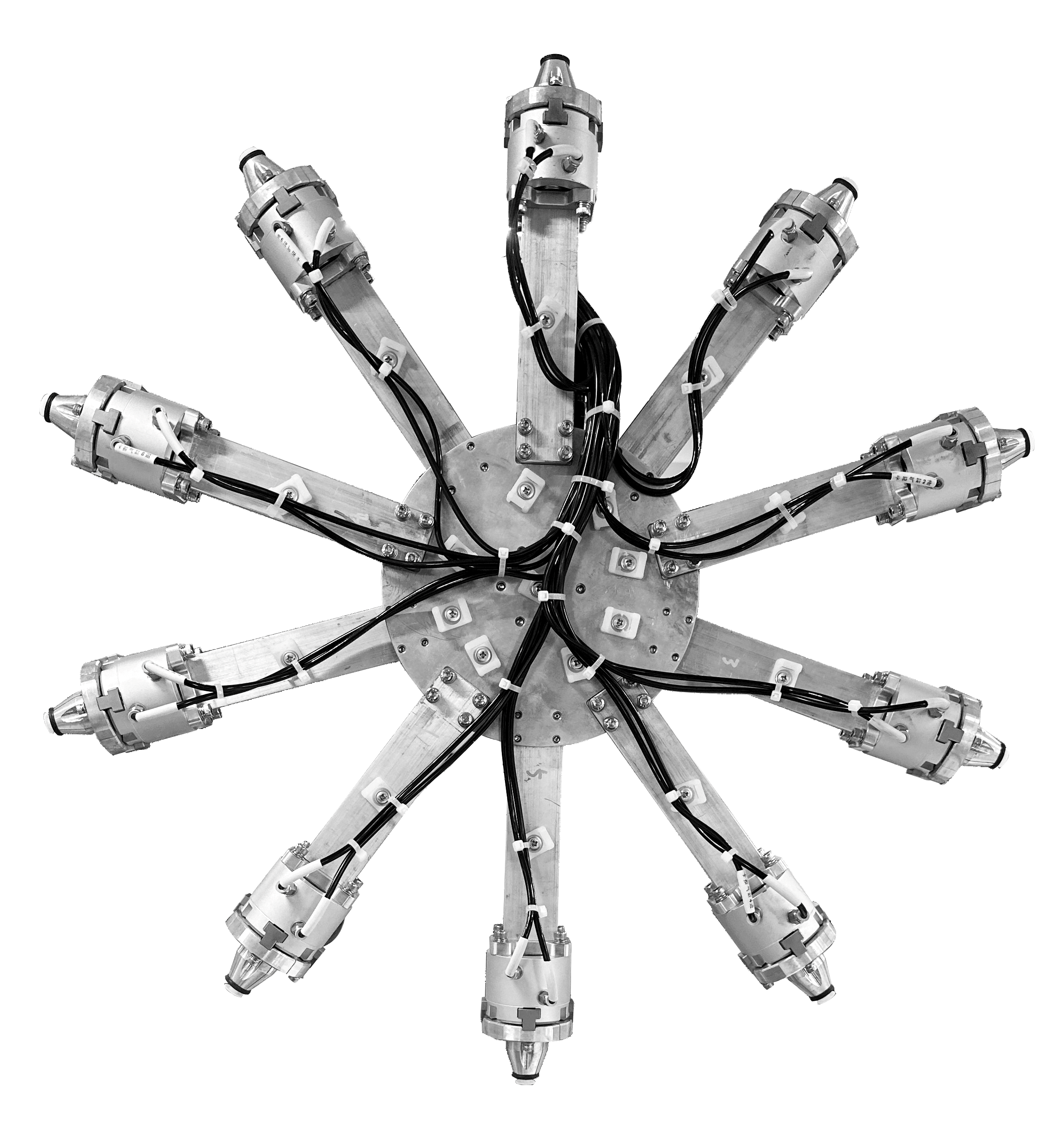

- 6-Axis Industrial Robot: Handles gripping and insertion with high flexibility.

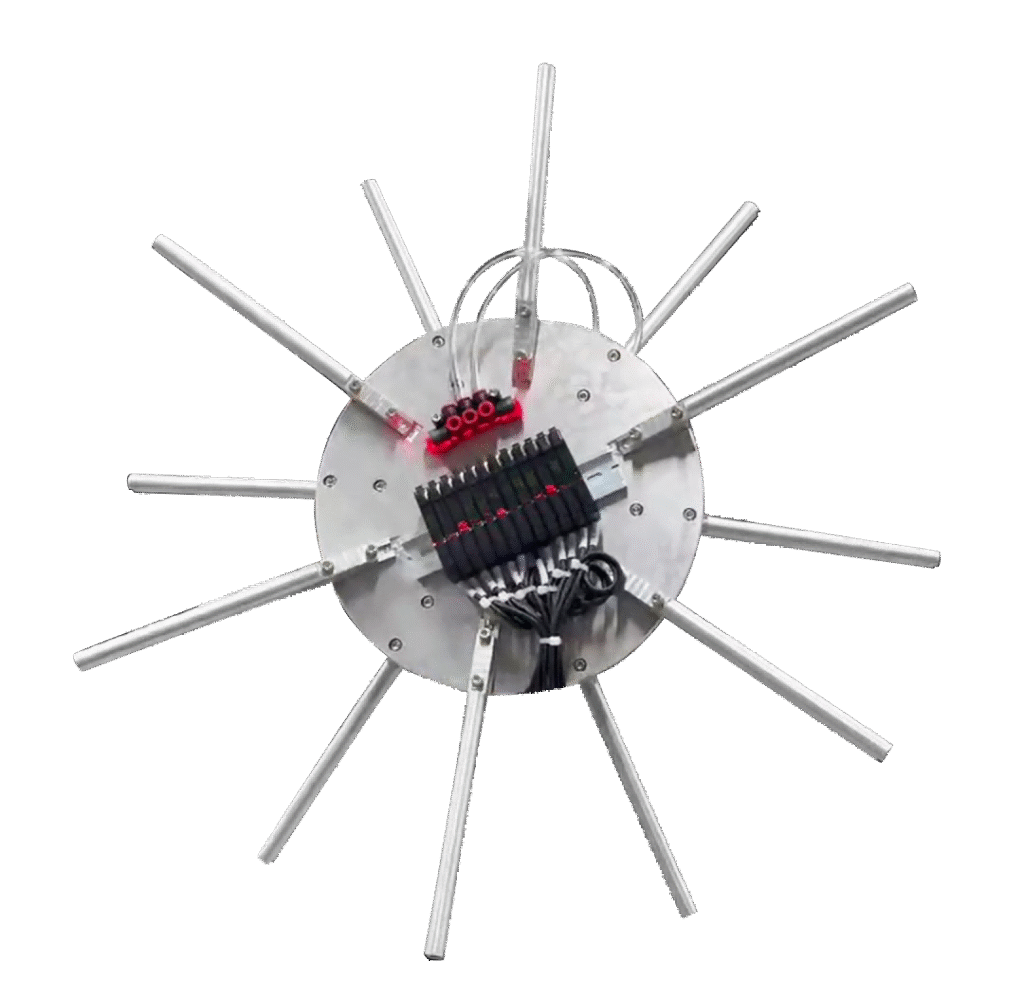

- Vision Camera System: Mounted on robot end-effector to identify clip position and detect errors.

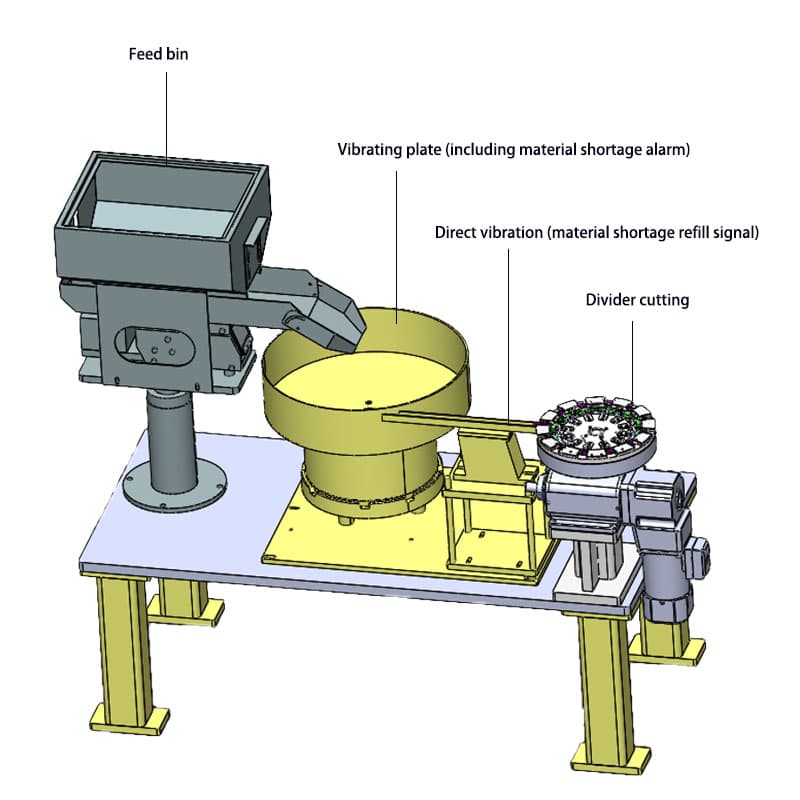

- Vibration Feeder System: Automatically aligns clips with ≤1% jamming rate.

- Pressing Cylinder Mechanism: Ensures stable insertion with precision control.

- Quick Mold Change System: Pneumatic lock for swift and precise mold switching (±0.5mm).

- Industrial Control Panel: HMI touchscreen supports MES integration.

Automated inserts clips equipment with 100% accuracy

Technical Features of robot inserts clips

Fully automatic clip insertion for injection-molded parts

≤50s cycle time excluding part loading/unloading

Mold change ≤10 minutes to support multi-model production

CCD vision system marks missing clips and notifies rework process

Clip missing rate ≤5%, vibration feeder jamming rate ≤1%

Integrated industrial PC with MES compatibility

Front cowl cover assembly

400 sets/day with >98% first-pass rate

Tailgate trim assembly

Cycle time < 45s, approved by OEM customer

EV engine compartment clip installation

Multi-model flexible production with zero error